The Essential Role of a Mold Manufacturer in Today's Industries

The manufacturing landscape has evolved significantly over the years, but one component has remained critical to production: the mold manufacturer. With industries increasing efficiency and reducing production costs, understanding the pivotal role that mold manufacturers play is essential for businesses looking to optimize their output and enhance product quality.

What is a Mold Manufacturer?

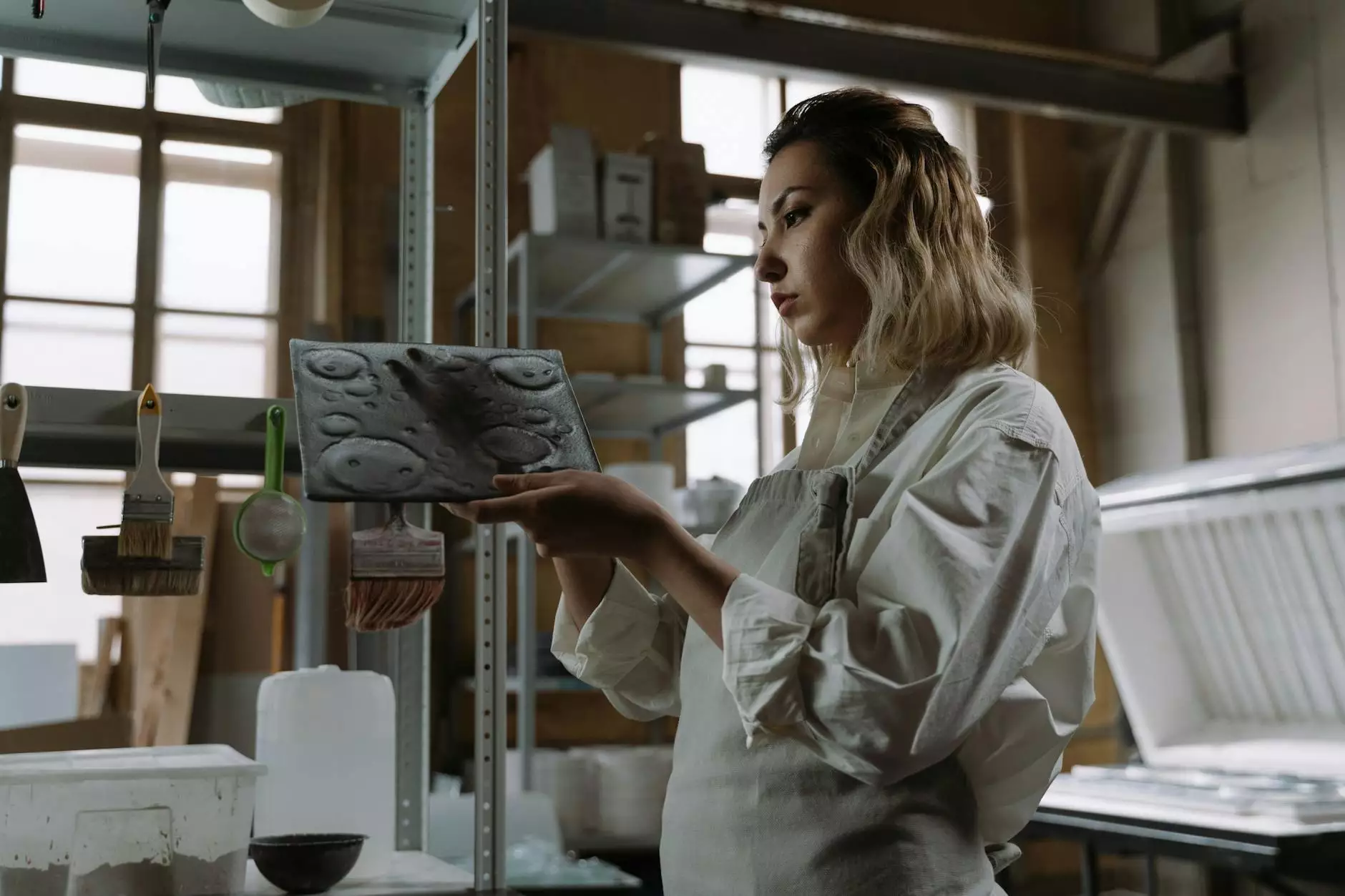

A mold manufacturer specializes in producing molds used for various manufacturing processes, particularly in plastic injection molding. These molds are essential for creating precise and complex parts for numerous applications, from automotive to consumer goods. By leveraging advanced technology and skilled craftsmanship, a mold manufacturer enables businesses to achieve high-quality production standards.

The Importance of Plastic Injection Molding

Plastic injection molding is one of the most common methods of manufacturing plastic components. It offers numerous advantages, including:

- Cost-Effectiveness: This process allows for high-volume production at a low cost per unit.

- Speed: It enables rapid production cycles.

- Complexity: Molds can produce intricate shapes with high precision.

- Material Efficiency: Minimal waste is generated compared to other manufacturing processes.

Without the expertise of a mold manufacturer, these benefits would be unattainable, as they design and produce custom molds tailored to specific production needs.

The Process of Mold Manufacturing

The process undertaken by a mold manufacturer involves several stages, which can vary based on the specific requirements of the industry. Here's a breakdown of the key steps:

1. Design and Engineering

The first step in mold manufacturing is the design phase. Using advanced software tools, engineers create detailed CAD (Computer-Aided Design) models of the mold. This is crucial, as it allows for:

- Precise Specifications: Ensuring the mold will meet the exact requirements of the product.

- Simulation: Testing the design's viability before physical production.

2. Material Selection

Choosing the right materials for mold construction is critical. Typically, molds are made from:

- Steel: Offers durability and is suitable for high-volume production.

- Aluminum: Lightweight and excellent for lower volume runs.

The choice of material affects the longevity and performance of the mold during the injection process.

3. Machining and Fabrication

Once the design is finalized and materials selected, machining begins. This involves:

- CNC Machining: Computer Numerical Control (CNC) machines are used to precisely cut the mold components.

- EDM Processes: Electrical Discharge Machining (EDM) is often employed for fine details.

This phase is where the mold starts taking shape, and precision is paramount to ensure that the final product meets quality standards.

4. Assembly

After the components are machined, the mold requires assembly. This includes:

- Fitting Together: All parts of the mold are meticulously fitted together.

- Testing Mechanisms: Movement mechanisms are checked to ensure proper operation.

This step is crucial, as any misalignment can result in defective products during the injection molding process.

5. Testing and Quality Control

Before a mold can go into production, it undergoes rigorous testing. This includes:

- Trial Runs: Initial injections are made to check for quality and precision.

- Adjustments: Any necessary modifications are made based on trial feedback.

Quality control at this stage ensures that the mold is capable of producing flawless parts consistently.

Benefits of Partnering with a Mold Manufacturer

Businesses that collaborate with a proficient mold manufacturer can experience several benefits, including:

1. Custom Solutions

Every business has unique needs. A quality mold manufacturer offers customized solutions tailored precisely to these requirements, ensuring optimal production lines.

2. Expertise and Experience

Established mold manufacturers bring a wealth of knowledge and experience, providing valuable insights that can enhance the manufacturing process. Their expertise often leads to innovation and improvements in design and production efficiency.

3. Time Efficiency

By utilizing the services of a mold manufacturer, businesses can expedite the production timeline, enabling them to bring products to market faster than ever. This is crucial in staying competitive within fast-paced industries.

4. Long-term Cost Savings

Although initial investment in quality mold manufacturing may be significant, over time, the durability and efficiency of well-made molds contribute to substantial savings in production costs.

Choosing the Right Mold Manufacturer

Selecting the right mold manufacturer is a critical decision that can affect your entire production process. Here are some key factors to consider:

- Reputation: Research the manufacturer's track record and customer reviews.

- Capabilities: Ensure they have the technology and skillset to handle your specific needs.

- Communication: A manufacturer that effectively communicates and collaborates will enhance the overall experience.

- Post-Production Support: Look for manufacturers that provide ongoing support and maintenance for their molds.

Future Trends in Mold Manufacturing

As technology advances, the mold manufacturing industry is continuously evolving. Some notable trends include:

1. 3D Printing in Mold Making

The integration of 3D printing technology has revolutionized mold making by allowing for rapid prototyping and complex designs that traditional methods cannot achieve.

2. Sustainability Practices

With an increasing focus on sustainability, many mold manufacturers are implementing eco-friendly practices in their processes, such as using recyclable materials and minimizing waste.

3. Smart Manufacturing Technologies

The adoption of IoT (Internet of Things) and smart manufacturing technologies is enhancing production efficiency and monitoring, leading to better quality control and quicker turnaround times.

Conclusion

The role of a mold manufacturer is vital across various industries, particularly in the domain of plastic production. By understanding the processes involved and the benefits of partnering with expert manufacturers like Hanking Mould, businesses can thrive in an increasingly competitive landscape. Investing in quality molds not only enhances product quality but also streamlines production, leading to greater satisfaction for both manufacturers and consumers alike.

As industries continue to advance, the significance of adept mold manufacturers will only grow, offering innovative solutions and paving the way for future developments. Companies looking to enhance their manufacturing capabilities would do well to prioritize collaboration with the best in the field to ensure their success in the marketplace.